The Asphalt Paving Association of Iowa (APAI) has honored a University of Iowa Technology Institute (ITI) faculty affiliate and student for their research into a cost-effective and eco-friendly pavement mix.

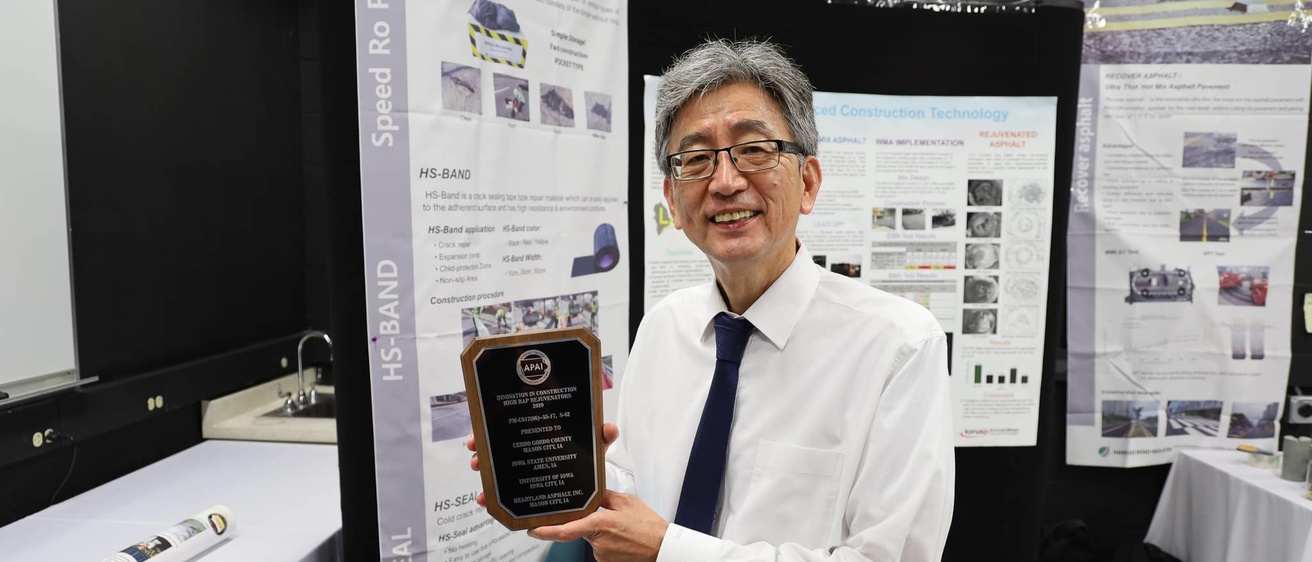

Hosin “David” Lee, a UI professor of civil and environmental engineering, was recognized with the APAI Innovation in Construction Award for his contributions to the successful construction of high reclaimed asphalt pavement (RAP) mixes with rejuvenators.

Byungkyu Moon, a UI graduate student who worked on this research project, received an APAI scholarship in 2020.

“The research by Dr. Lee and others on rejuvenators is extremely important to determine if higher percentages of RAP can be allowed in mix designs, which ultimately will improve the sustainability of asphalt pavements and be a benefit to the driving public,” said Scott Dockstader, executive vice president of APAI.

The APAI Innovation in Construction Award is an annual award that honors contractors, agencies, and higher education institutions for creating and advancing cutting edge technologies and methods to build innovative hot mix asphalt pavements.

The APAI Executive Committee provided the Innovation in Construction Award in recognition of dedicated efforts of Cerro Gordo County, Iowa State University,

the University of Iowa, and Heartland Asphalt, Inc., who contributed to the successful construction of high RAP mixes with rejuvenators.

Increasing the RAP contents in pavement mixes is more environmentally friendly, as it requires less demand for new materials to be added into the mix.

Iowa Department of Transportation specifications allow limited use of RAP in hot mix asphalt (HMA) paving mixtures.

“Mixes with high percentages of RAP are less ductile and are more prone to cracking than traditional pavement,” said Lee, who directs the Laboratory for Advanced Construction Technology (LACT) at ITI. “Adding innovative rejuvenators decreases the drawbacks to high RAP mixes and allows the pavement to withstand more stresses without cracking.”

The major advantage of RAP is the financial savings that it can potentially achieve over conventional HMA by eliminating costs associated with transporting, processing, and stockpiling asphalt binder and aggregates. RAP contains valuable bituminous material and aggregates that, when allowed in mixes, can greatly reduce the price of building new pavements.